Absorber: VyBar® Marine 48F & 848F – Marine Soundproofing

Description

VyBar® is a rigid marine noise barrier and vibration damping sheet specifically engineered to combat the challenging combined effects of vibrations, sound transmission and reverberation from marine engines and boat hulls.

Applications

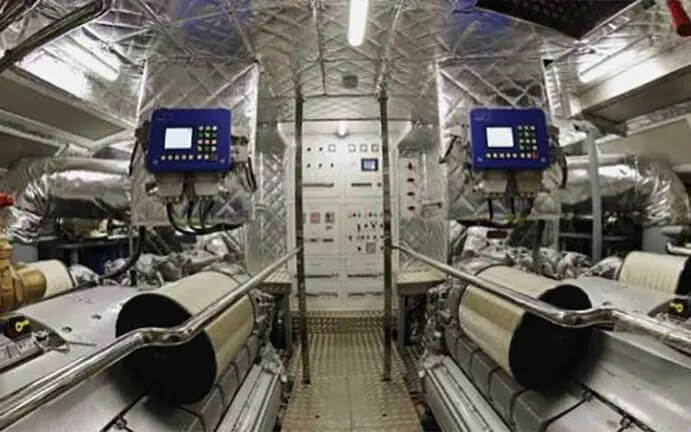

- Engine enclosures

- Bulkhead

- Partition walls

- Plant rooms

- Mechanical service rooms

key benefits

- High sound absorption, resilience and compression loading capability in one product

- Specifically designed for the marine industry, but is also suited to various industrial applications

- Low cost and long lasting

- Unaffected by vibration, oil, water and hydrolysis

- Easy to handle, cut and install

features

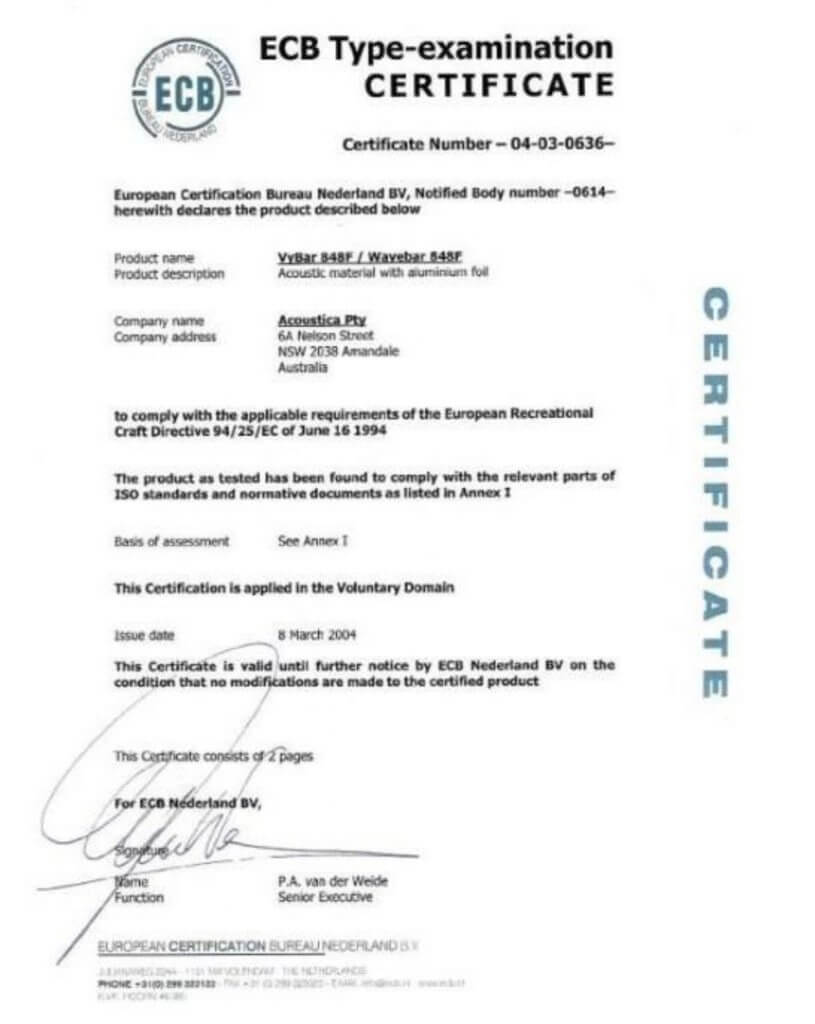

- Marine regulations compliant - tested and certified to meet marine technical requirements and resolutions, fire rated to international standards

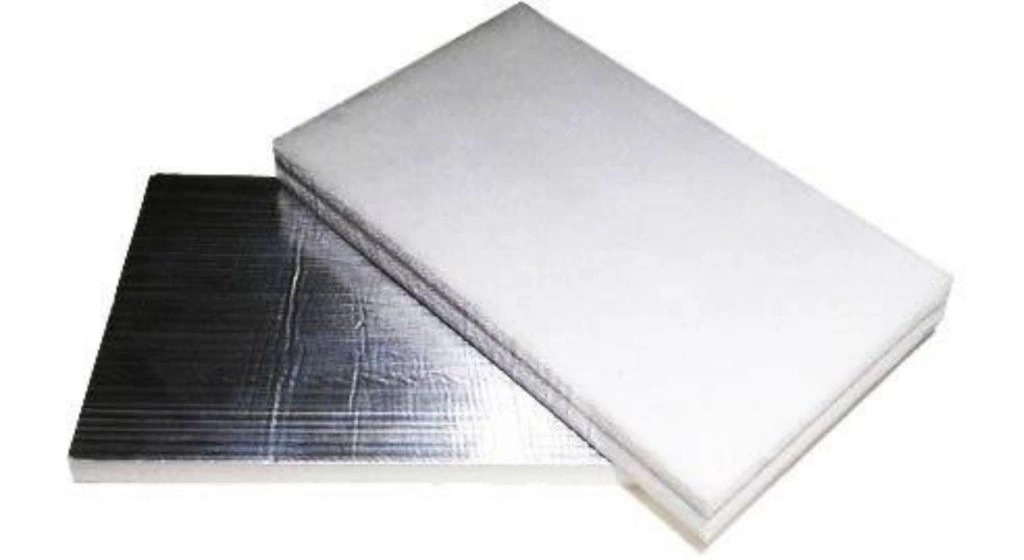

- Sheets of thermally bonded, 100% polyester fibre, semi-rigid laminate, with an aluminium foil facing on one side

- Available in 10mm or 20mm thickness

- Service temperature is -50 to 180°C

- Heat resistant up to 180°C

- 10-year guarantee

- Environmentally safe

- Easy cutting with any sharp blade

- Made in Australia

standards fire rating

Group 1

Fire rated according to AS1530.3

CSIRO tested and certified – meets the requirements for low flame spread of a bulkhead, wall and ceiling lining in accordance with IMO Resolution A.653 (16) as amended by resolution MSC 61 (67) as specified by the International Convention for the Safety of Life at Sea, 1974.

In compliance with the essential requirements of the Marine Equipment Directive 2014/90/EU, as amended by 2015/559/EU Service temperature -50 to 180C (no direct contact with heat source)

VyBar® Marine has been tested by the CSIRO and certified that it meets the requirements for low flame spread of a bulkhead, wall and ceiling lining in accordance with IMO Resolution A.653 (16) as amended by resolution MSC 61 (67) as specified by the International Convention for the Safety of Life at Sea, 1974 and the technical requirements of the amended IMO resolution MSC61 (67), Annex2, section 2.2.

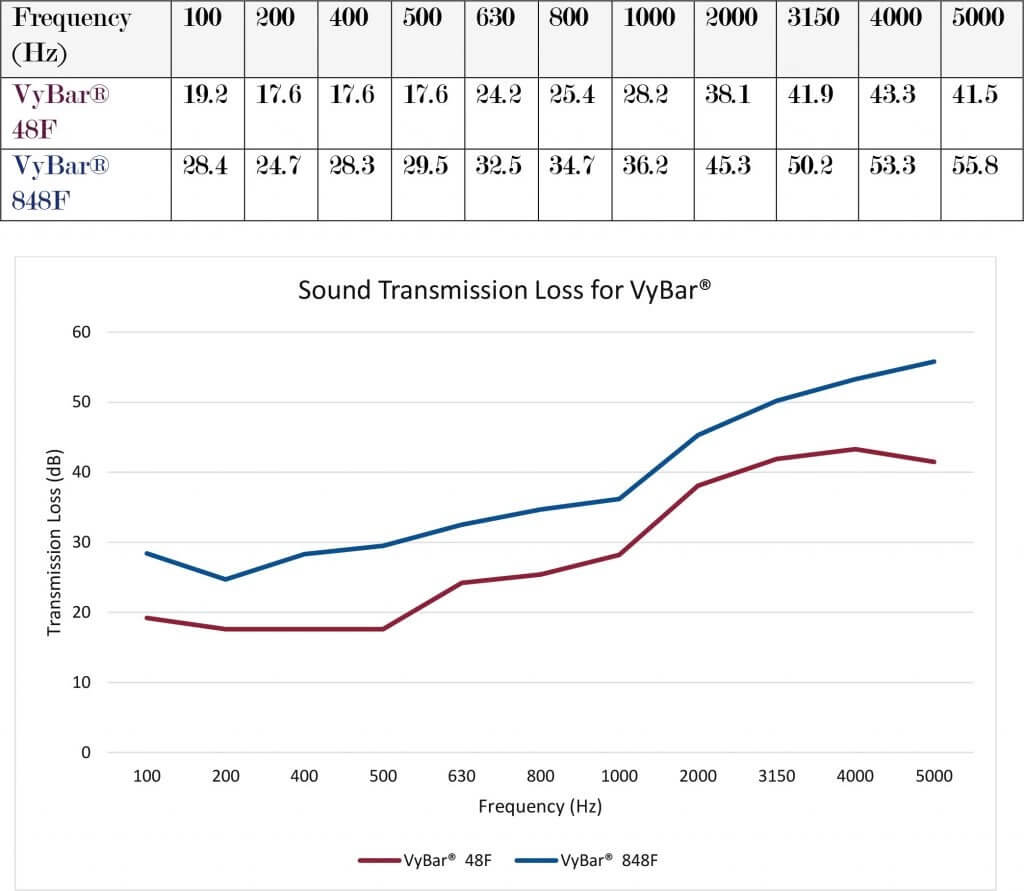

Scores & Test Results

Construction

For optimum benefit, VyBar® Marine must be properly installed. Where airflow is required, expert advice should be sought from our engineer, as acoustic baffles may be required. Any seal must be airtight for best results.

If the vessel is being insulated against both sound & fire, welded metal or bimetal pins are recommended to install.

If the vessel is being insulated against sound, adhesive PVC pins are acceptable.

Pins should be installed starting 200mm max from material edges in a 300x300mm grid pattern.

If there is a space between the VyBar® Marine and the surface it is being adhered to, a backing washer should be installed on the pin prior to installing the material. This will ensure a secure fixing.

All edges & joints must be taped with an alloy foil tape, please feel free to ask Acoustica Projects about ordering the aluminium foil tape we provide.

Fire resistant glue is recommended.

When cutting to install always leave a 2-3mm margin all around for a tight fit even when cutting from a pattern.

If the product is being laminated with other materials a fire-resistant glue is recommended.

Acoustica Projects / Acoustica Projects Newcastle

Visit our Showroom

Our talented project managers have over 100 years combined sound proofing experience.

Taking a holistic approach our staff are available to provide any guidance and advise on the best soundproofing and noise reduction solution to meet your needs.

BRANDS WE WORK WITH

Our Past Projects

We have experience working on a diverse range of projects and whether it be for your walls, floors ceilings, studios, meeting rooms, restaurants, sports halls and schools we can get it done! If you are a sound technician, or in the acoustics business or you are a novice we are happy to work with you and guide you on how soundproofing and noise reduction can help you!