Panel Bond

Acoustic Solutions You Can Trust

dedicated

project manager

One-Stop

Shop

Manufactured in Australia

Panel-Bond:Choosing the Right Adhesive for Acoustic Panels

To get the best results when mounting acoustic panels, pick your

glue carefully.

Panel-Bond is

a good adhesive choice because it helps keep the panels stuck where they belong—which means

they’ll keep doing their job (absorbing sound) and not damage walls or ceilings either!

With so many adhesives available, it’s important to select one made specifically for use with

acoustic panels.

Panel-Bond was designed for this exact purpose; it provides a strong initial bond yet remains

flexible and easy to work with—whether you’re applying it to walls or ceilings.

Here, we’ll discuss why using the correct adhesive is so important when installing these types of

products as well as various factors worth considering. Finally, discover how

Panel-Bond can

make your life easier regardless of whether you’re a professional tradesperson or an

enthusiastic DIY-er!

Why the Right Adhesive Matters

Isn’t it interesting how your choice of glue directly influences the effectiveness and longevity of

acoustic panels?

The incredible tack strength of Panel-Bond means it holds fast, so you can mount panels on

walls or ceilings without mechanical fixings– in most cases.

Choose the correct adhesive and you’ll enjoy benefits such as:

– Reliable, long-term performance

– Consistent sound absorption

– Panels that come off without damaging paintwork or leaving marks

Panel-Bond also stays flexible when bonding joins absorb any movements or vibrations helping

maintain the appearance and function of your acoustic solution for longer.

Key Factors in Selecting Panel Adhesive

When selecting panel glue, think about the surface type, how strong the bond needs to be, how

long curing can take, and also whether it is suitable environmentally.

Panel-Bond works with various materials: plasterboard, concrete, MDF, plywood timber

battens plus painted or primed surfaces. It can also accommodate many panel thicknesses–

from 25mm all the way up to 100mm.

Here are some reasons why it is great:

– It has a strong initial grab so you don’t need to hold things for ages

– Sets quickly– you can fix panels in place within about five minutes

– Low odour/ VOC meaning there are no harmful fumes making it safe for indoor use

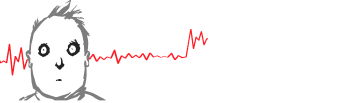

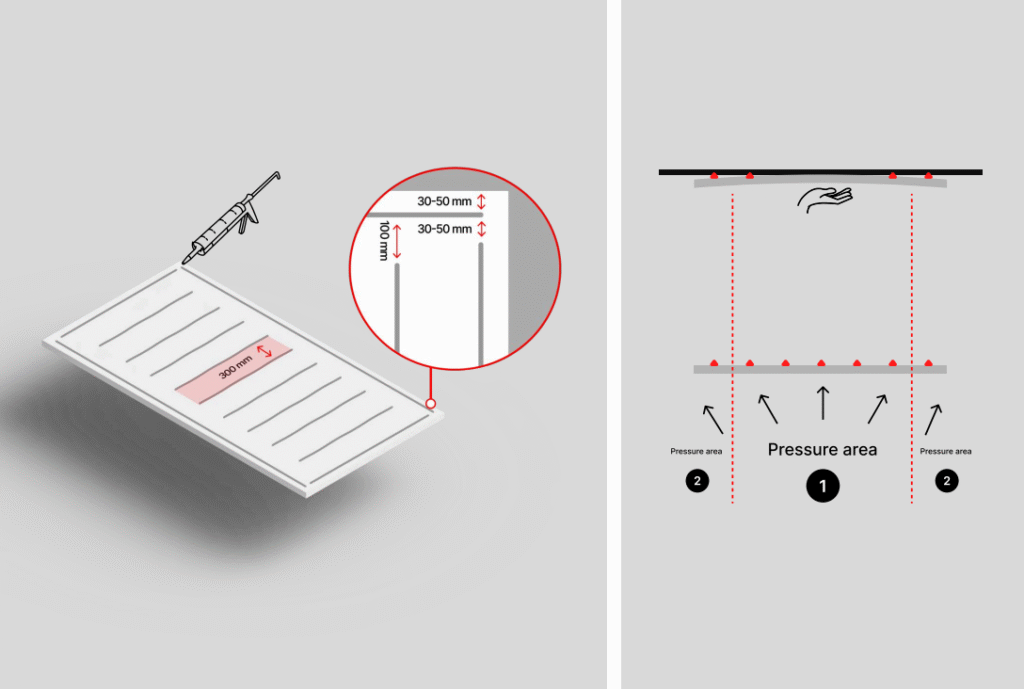

Application Tips for Optimal Results

To ensure a professional finish:

1. Clean and dry all surfaces, removing dust, oil, or loose material.

2. Lightly sand glossy or sealed surfaces to improve adhesion.

3. Apply Panel-Bond in beads every 300mm across the panel, with a perimeter bead 30–50mm

from the edge, stopping 100mm short to prevent squeeze-out.

If you’re looking for a reliable way to attach acoustic panels, forget about the old methods and

give Panel-Bond a try!

It’s really strong but still easy to use- perfect for walls and ceilings.

And because it’s designed specifically for this job, it creates a bond that lasts: neat finishes with

great sound results.

When you use an adhesive like this one along with good preparation there is no reason why

your installation shouldn’t both look fantastic… as well as do its job!

LET US HELP YOU TODAY

Looking For A Creative Solution?

Contact Us

Follow Us

- © 2024

- Acoustica Projects

- All Rights Reserved.

Website by Blackwater Social Marketing